The peach pitting machine model 350 APA-Vision, a technological evolution of the model 320 APA-E, is equipped with a fruit position detection system managed by a programmed logic controller (PLC).

The machine is capable of pitting “freestone” and “clingstone” type peaches at a mechanical speed of 350 fruits per minute.

General informations

Thanks to the innovative PLC driven recognition system, the machine is capable of detecting the correct positioning of a fruit and removing from the conveyor belt the fruits not correctly positioned, recycling them in the feeder, with the result of improving the orientation efficiency and decreasing dramatically the presence of pit fragments. The system is composed as follows: - A station that detects the fruit position and communicates to the PLC the information. - A pickup stage that, in function of the information received by the PLC, removes from the conveyor belt the fruits not correctly positioned during the passage through the mechanical orienting systems. - A system of recycle that transports to the feeder the fruits removed by the pickup system. - The new automatic continuous orientation system (patented internationally) guarantees already a percentage of well oriented fruits equal to the torque pitting system (average efficiency of 90%) and without any labor, unlike the non continuous aligning systems. - With the implementation of the Vision system, the final percent of orientation can surpass 95%. - The high percentage of correctly positioned peaches, combined with the pitting system with 360° rotation of knives, driven by a brushless motor with high number of rotations per minute, guarantees a superior quality of the cut, absence of stick pits and a lower amount of pit fragments, ensuring a reduced employ of labor for the operations of inspection and reprocessing of the peaches after pitting.

Functionality

- High capacity. - Completely automatic. Does not require manpower. - A better orientation performance compared to any other machine, both knife and torque. - A more uniform cut thanks to the high speed spinning knives - Less mechanical wear, thanks to the absence of knives rotation for the repositioning. - Reduced employ of manpower for the operation subsequent to pitting, thanks to the automatic system of orientation and recognition of the fruit position, which generates less pit breakages and helps decreasing presence of pit fragments inside the pitted fruits. - The machine is made in compliance with the highest sanitary standards. All the parts in contact with the product are “food grade”. Frame and covers of the machine are in stainless steel. - The pitter complies with the European regulations for safety, Directive 2006/42/CE and subsequent modifications as reference rules. - The peaches are fed into the pitter hopper, which feeds individually the eight sockets of each flight. The peaches, crossing the orientation sections, are positioned and aligned along the suture line. In the pitting station, the pitting knives, driven by a brushless motor, rotate of 360° at high speed, separating the pit from the pulp. At the same time, the cutting group cuts the fruit in two halves.

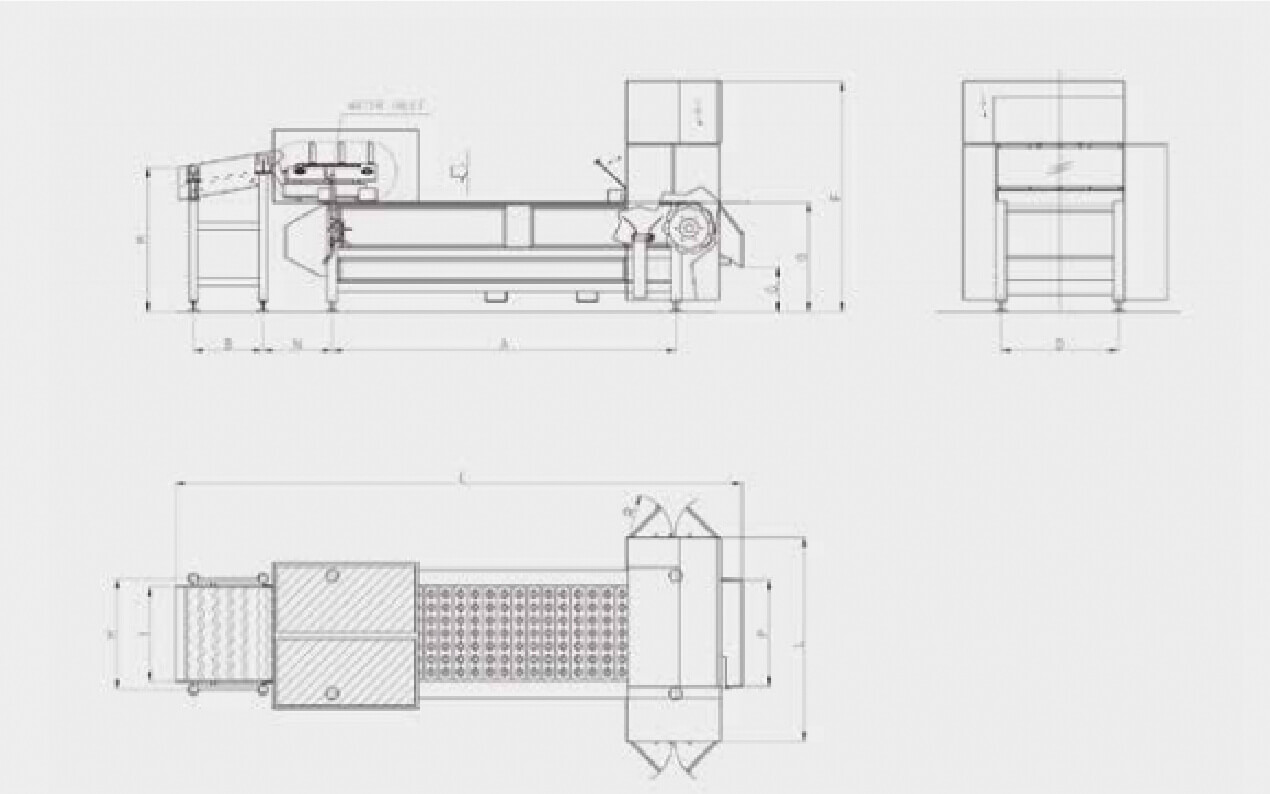

Dimensions:

Lenght:5.500 mm

Width:1.980 mm

Height:2.240 mm

Weight:2.300 Kg

Peach pitting machine model 350 APA-VISION

The peach pitting machine model 350 APA-Vision, a technological evolution of the model 320 APA-E, is equipped with a fruit

Open 3D Video